Introduction

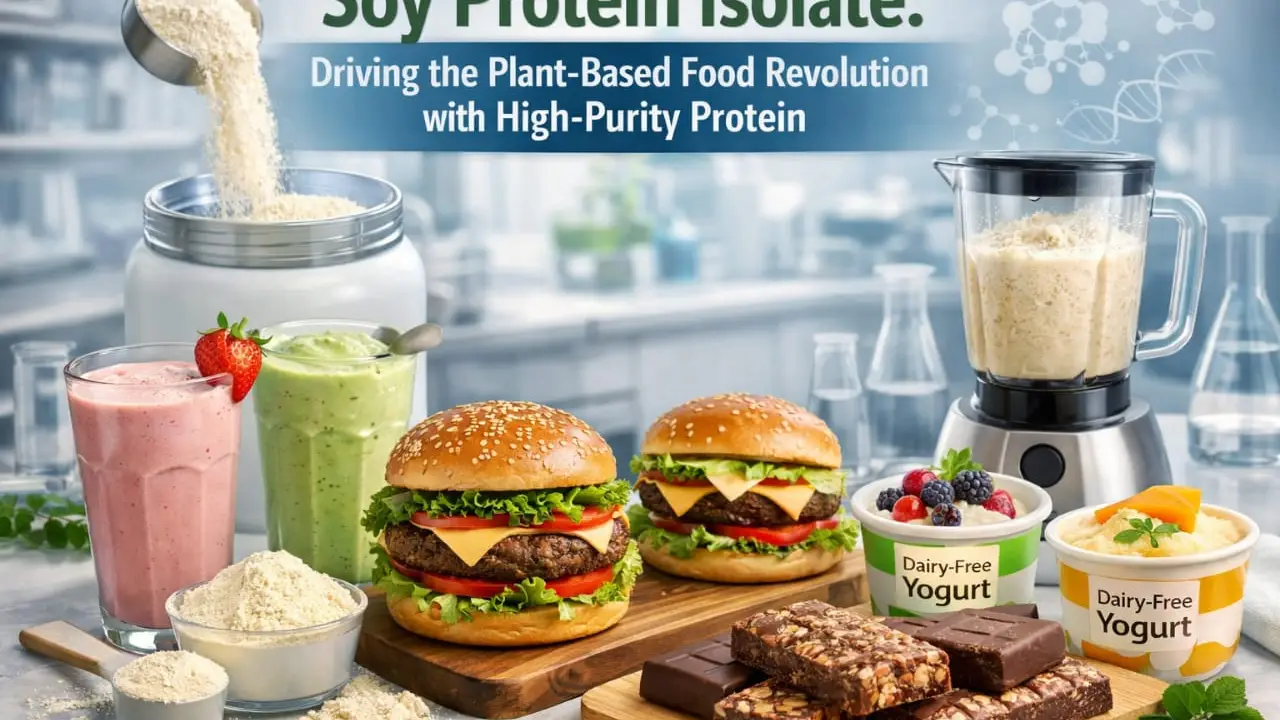

The global food landscape is undergoing a dramatic transformation. Health-conscious consumers, environmental sustainability concerns, and animal welfare considerations are fueling rapid growth in plant-based alternatives. At the heart of this revolution lies soy protein isolate (SPI), a high-purity, versatile ingredient that enables manufacturers to replicate the sensory, nutritional, and structural properties of animal-derived foods.

With protein content exceeding 90 percent, SPI has become a cornerstone ingredient for plant-based meats, dairy alternatives, protein beverages, fortified snacks, and sports nutrition products. Its combination of nutritional density, functional versatility, and clean-label appeal makes it indispensable for food scientists, R&D teams, and manufacturers seeking innovation while meeting modern consumer expectations. This article explores SPI’s technical characteristics, production processes, nutritional benefits, functional properties, and market trends. It also highlights the importance of sourcing from reliable suppliers such as Chemtradeasia, ensuring consistent quality, safety, and compliance.

Understanding Soy Protein Isolate

Soy protein isolate represents the most refined form of soy protein. Fats and carbohydrates are removed from defatted soybean flakes, resulting in a powder containing over 90 percent protein. The neutral flavor, fine texture, and excellent solubility make SPI ideal for beverages, dairy alternatives, meat analogues, and functional foods.

The protein content is largely comprised of globular storage proteins, including glycinin and beta-conglycinin. These proteins support gelation, emulsification, and water and fat binding, which are essential for replicating meat textures, stabilizing dairy alternatives, and improving mouthfeel. Food-grade SPI meets rigorous standards such as NSF, USP, FDA, and EU guidelines. Non-GMO or identity-preserved options further support clean-label and sustainable product claims.

The Manufacturing Process: From Soybean to Premium Isolate

Producing SPI involves several steps designed to maximize protein purity and functional integrity:

- Cleaning and Dehulling: High-quality soybeans are cleaned and dehulled.

- Defatting: Oils are removed using solvent extraction, producing low-fat soy flakes.

- Protein Extraction: Flakes are mixed with water under alkaline conditions to solubilize proteins.

- Separation: Insoluble carbohydrates are removed via centrifugation.

- Isoelectric Precipitation: Proteins are precipitated at a pH of approximately 4.5.

- Washing, Neutralization, and Drying: Protein curds are washed, neutralized, and spray-dried into fine powder.

Some manufacturers use ultrafiltration to preserve protein structure and improve solubility. Quality control at every stage ensures minimal off-flavors, consistent protein content, and functional performance suitable for demanding food applications.

Nutritional Profile and Health Benefits

SPI delivers a complete amino acid profile, including all nine essential amino acids, with a PDCAAS score of 1.0, equivalent to animal proteins. Its low fat and carbohydrate content supports high-protein, low-calorie, and nutrient-fortified formulations.

Health benefits include:

- Supporting muscle synthesis and tissue repair

- Promoting heart health by helping lower LDL cholesterol

- Providing plant-based nutrition that is naturally lactose- and gluten-free

These properties allow manufacturers to produce protein shakes, bars, meat analogues, and dairy alternatives that combine nutritional density with taste and texture.

Functional Benefits in Food Applications

SPI’s functional attributes enhance both product performance and consumer experience:

- Water and Fat Binding: Retains moisture in meat analogues and improves texture in bakery and snack items.

- Gelation: Creates fibrous, meat-like textures in plant-based meats.

- Emulsification: Stabilizes beverages, dressings, and dairy alternatives.

- Solubility: Ensures smooth dispersion in powders and ready-to-drink formulations.

These properties enable SPI to perform consistently across various processing conditions, pH ranges, and product formats.

Applications Across the Plant-Based Food Sector

Dairy Alternatives

SPI fortifies protein content in soy milk, yogurts, creamers, and cheese alternatives, typically contributing 8–10 grams per serving. It stabilizes emulsions, replaces animal-derived proteins like casein, and maintains creamy texture, heat stability, and shelf-life reliability.

Meat Analogues

In plant-based burgers, nuggets, and sausages, SPI acts as a binder, mimicking the fibrous structure and juiciness of meat. Inclusion rates of 2–5 percent can improve yield by up to 20 percent, making SPI essential for scalable production.

Bakery, Snacks, and Functional Foods

SPI enriches protein in bars, extruded snacks, cereals, and fortified foods. It enhances texture, binding, and mouthfeel without altering flavor, supporting clean-label and high-protein product claims.

Beverages and Sports Nutrition

Its dispersibility ensures smooth, lump-free beverages. SPI delivers 20–30 grams of protein per serving, making it a preferred ingredient for ready-to-drink shakes, sports drinks, and meal replacements.

Market Trends Driving SPI Adoption

The plant-based food market has grown significantly, exceeding $30 billion in 2025 and projected to reach $162 billion by 2030. Growth is fueled by health-conscious, vegan, and flexitarian consumers. Key drivers include:

- High-protein, low-fat, and cholesterol-free nutritional benefits

- Sustainability advantages compared with animal proteins

- Clean-label preference for non-GMO, minimally processed ingredients

- Regional growth with Asia-Pacific leading adoption due to urbanization and health trends, and Europe emphasizing allergen-free and organic products

SPI is central to these trends, enabling manufacturers to meet technical, nutritional, and regulatory requirements.

Advantages for Manufacturers

SPI offers several advantages for food developers:

- Cost-effective high-protein ingredient that reduces inclusion rates and production costs

- Functional versatility across pH, temperature, and product formats

- Reliable quality that supports large-scale production

- Facilitates nutritional and clean-label claims, aiding marketing and regulatory compliance

Choosing certified suppliers ensures traceability, batch consistency, and adherence to global standards, minimizing risk and enabling innovative product development.

Storage, Handling, and Safety Considerations

Proper storage and handling are critical to preserve SPI functionality:

- Store in a cool, dry, and ventilated environment below 25°C and 60 percent relative humidity

- Maintain a shelf life of up to 24 months under proper conditions

- Minimize dust and use personal protective equipment to prevent contamination

- Transport in sealed, temperature-controlled packaging for bulk shipments

Following these practices ensures consistent product performance and safety in food-grade and plant-based manufacturing.

Conclusion

Soy protein isolate has emerged as a foundation ingredient in the plant-based food revolution. Its combination of high-quality protein, functional versatility, and clean-label appeal enables manufacturers to create products ranging from plant-based meats and dairy alternatives to fortified snacks and beverages.

Consumer demand for sustainable, nutritious, and ethical foods continues to grow, making SPI increasingly essential. Sourcing from trusted global suppliers such as Chemtradeasia provides access to high-quality, traceable, and compliant SPI, ensuring reliable performance, regulatory alignment, and supply chain security.

In the competitive plant-based market, soy protein isolate is not only an ingredient but a strategic enabler for innovation, growth, and success.

Leave a Comment